Our article on misconceptions for adsorption dryers raised many questions. We will therefore go further on the point which aroused the most curiosity, drying at low relative humidity (downstream of refrigeration dryers) and the impossibility of saving the regeneration air.

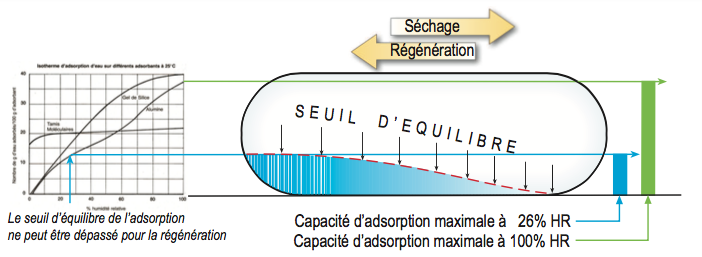

An essential thing to know, the desiccant, for a given hygrometry, cannot adsorb beyond its maximum equilibrium value (see B.A.S. of January). The second thing just as important, the regeneration air cannot be charged with humidity beyond this same equilibrium threshold.

The graph above indicates the adsorption capacity of the desiccant according to the relative humidity and, in a synoptic way, what happens in the dryer tank (shown here horizontally for illustration purposes).

Take a compressed air temperature of 25 ° C with a dew point of + 3 ° C. The relative air humidity is 26% (5.95 g / 22.8 g). At this humidity, the alumina (1) cannot adsorb more than 130 g of water vapor per kg.

The maximum adsorption at the inlet of the tank will be 130 g / kg, to decrease as the drying process progresses along the desiccant column.

To save regeneration air, the “natural” idea consists in making the ratio of water weights (in our case 39.3 / 5.95, that is 6.6 times less water (2)) and lengthen the adsorption cycle accordingly. For a 4-minute cycle, this would give 4 x 6.6 or 26 minutes of adsorption. If this approach works for adsorption (3), the problem is during regeneration. This part of the cycle cannot be lengthened (otherwise no savings) and must be able to completely desorb the desiccant. To simplify - by excluding the time necessary for repressurization - during a regeneration of 4 minutes the air will have to evacuate in 1 volume the charge of water deposited in 26 minutes by 6.6 volumes of air at low relative humidity.

Hence the desorbtion equation:

1 volume at 39.3 g (100% R.H.) = 6.6 volumes at 5.95 g (26% R.H.), which is obviously false!

This would lead to admitting that - during regeneration - the desiccant can load to the maximum of its capacity (green line) which is impossible. Why ? Because the regeneration air cannot exceed the equilibrium hygrometric value of the adsorption phase. (Or in our example 26%). Regeneration air with a higher value would be dried by the desiccant, which is the opposite effect to the desired goal!). We realize here that this only volume of sweeping air cannot regenerate the desiccant. As we have already seen in the February issue, for regenerative dryers with no heat input, the 1: 1 rule (1 volume of dried air = 1 volume of regeneration air) is immutable.

Thus, even with a cycle control by hygrometer, a heatless dryer used at its nominal capacity cannot save energy under the pretext of drying air with low relative humidity. In the short term, the residual water accumulated in the desiccant will charge the column with water vapor and lead the cycle to gradually return to its standard value. The dryer will then behave like a conventional heatless dryer, i.e. 15% regeneration at 7 bars.